ALD Research

Atomic layer deposition (ALD) is a process for depositing thin films in a slow but very precise way. It’s better to think of growing films a few atoms at a time rather than depositing them. Chemical vapor deposition (CVD) is also a film “growth” technique, but in CVD, films are grown at somewhat higher temperatures using chemicals that don’t spontaneously react with each other. In CVD, the chemicals react with a hot surface to form the film.

In ALD, more reactive chemicals are used so that the surface temperature can be lower (e.g., maybe the surface is plastic and would melt at higher temps). Since the chemicals are more reactive, the surface can be cooler, which is good, but the chemicals also can react with each other in as vapors, which is typically bad. To prevent this, the chemicals are added to the surface sequentially until they can’t react with the surface any further, and this process is repeated over and over. In this way, films are grown in a cyclic, layer-by-layer manner where the amount of material that is deposited in each cycle is controlled by self-limiting surface chemistry (cool!).

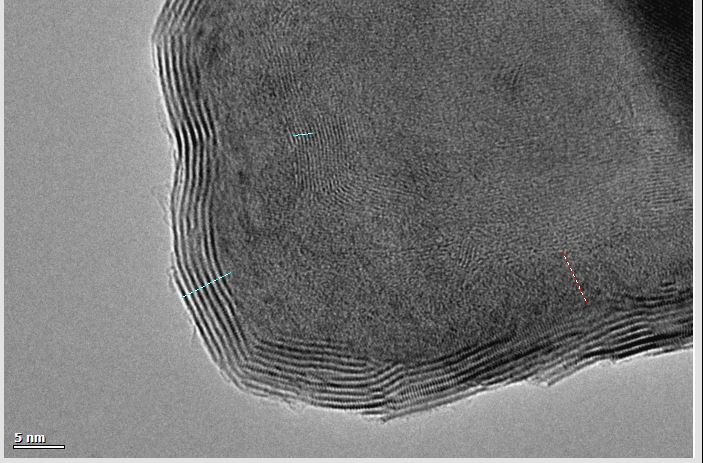

There are lots of good cartoons and references for learning more about ALD. The Atomic Limits website has an extensive list of ALD processes and an image library with many illustrations of key ALD concepts and examples of ALD films.

ALD Systems

- In our group, we use homebuilt ALD systems as well as a commercial system that we modified.

- Our tube furnace ALD system was initially built by students at

Rollins College in 2007. Since then, it has undergone some major

overhauls and upgrades. The reflections in the photo are from the wall

of the walk-in fume/heat capture hood.

- Four manifolds with separate inlet ports; capable of full stop flow (12500:1 aspect ratio record).

- In situ QCM and RGA.

- Multiple stages of abatement.

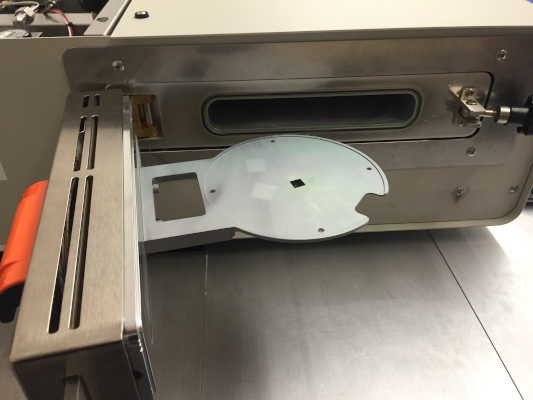

- Arradiance ALD system

- Two inlet manifolds, each with four ports

- 150 mm sample diameter

- In situ QCM and RGA